GLASS GLOSSARY OF TERMS

Annealed glass:

Standard float (plate) glass.

Awning window:

Has a top hinge and swings outward from the bottom for ventilation.

Argon gas:

An inert, nontoxic gas used to fill insulating units for improved thermal performance.

Balance system:

The use of springs or weights to hold a vertical sash in any desired position.

Bay window:

An arrangement of three or more individual window units attached to each other. In a typical three-unit bay, a center section usually remains fixed while the two on either side act as individual casements.

Bent glass:

A glass curved through a special process.

Beveling:

The process by which an edge of glass is finished to an angle so that the edge is not perpendicular to either face of the glass.

Block:

A piece of neoprene, silicone, or other suitable material used to position glass in a frame.

Bow window:

A bow window can be arranged with three or more equal width units. They can be fixed or operable or mixed in any combination. They are usually mulled together with a small angle such as 13 degrees.

Butyl:

A synthetic rubber that can be used both as a sealant and architectural glazing tape.

Cam:

A piece that connects with the keeper mechanism to keep the window sashes together when locked.

Casement window:

A window unit in which the single sash cranks outward to the right or left.

Caulking:

A putty-like compound used to block exterior air or moisture leaks where two surfaces meet and have minimum movement. Large cracks can be stuffed with mineral wood and weather sealed with caulking.

Condensation resistance factor:

A measure of the effectiveness of a window to reduce condensation. A higher number means better efficiency.

Curtain wall:

An exterior building wall which carries no roof or floor loads. It consists entirely of metal, or a combination of metal, glass and other surfacing materials supported by a metal framework.

Deadlight:

A piece of glass with a sash around it.

Double glazing:

Two panes of glass enclosing a hermetically-sealed air space.

Double-hung window:

A window consisting of two sashes of glass operating in a rectangular frame, both the upper and lower halves can be slid up and down and usually use a counter balance mechanism to hold the sash in place.

Dry glazing:

A method of securing glass in a frame by use of a dry, preformed resilient gasket, without the use of a compound.

Egress code:

A law requiring a minimum opening of a window for persons to exit or firefighters to enter.

Etching:

Patterns or designs cut into glass either by acid etching or needle etching techniques.

Fixed window:

A window which is stationary, also known as a picture window. Can also refer to: the part of a sliding window or door which is non-moveable, also known as inactive.

Float glass:

Glass which has its bottom surfaces formed by floating on molten metal, the top surface being gravity formed, producing a high optical quality of glass with parallel surfaces and, without polishing and grinding, the fire-finished brilliance of the finest sheet glass. Float is replacing plate glass.

Flush glazing:

A method of glazing wherein the surfaces of the glass retaining members (stops or beads) are in the same plane normal to the glass as the side faces of the frame members; often achieved by providing pockets in these faces

Fogging:

A deposit of contamination left on the inside surface of the sealed insulating glass unit due to extremes of temperatures. Fogging ultimately resulting in seal failure.

Gaskets:

Pre-formed glazing materials used for bedding or securing glass and for separating glass from the frame.

Geometric windows:

Specially designed to create rectangles, triangles, half-rounds, full-rounds, ellipses and more

Glazier:

Buys glass and installs it on a “contractor” basis. Examples: installing the window system in large office buildings, shopping center malls, etc.

Glazing:

The process of installing glass in a frame.

Glazing compound:

A soft dough-like material used for filling and sealing the space between a pane of glass and its surrounding frame.

Head:

The horizontal portion at the top of the main window frame.

Head expander:

A u-shaped piece of vinyl placed on the head of a window to be used as filler. This piece will expand or lengthen a unit and fill a gap.

Heat-strengthened glass:

Glass which is reheated, after forming, just below melting point and then cooled. A compressed surface is formed which increases its strength. Used for spandrel glass.

Hermetically sealed unit:

An insulating glass unit made up of two lights of glass, separated by a roll formed aluminum spacer tube (at the full perimeter) which is filled with a moisture absorbing material. The unit is then completely sealed, creating a moisture-free, clean dead air space

Inner pane:

The pane of a double-glazed unit which faces the interior of a building.

Insulating glass:

Insulating glass refers to two pieces of glass spaced apart and hermetically sealed to form a single-glazed unit with an air space between. Heat transmission through this type of glass may be as low as half that without such an air space. It is also called double glazing.

Interior glazed:

Glass set from the interior of the building.

J-channel:

Used around the exterior of a window where the siding fits. It extends beyond the window to the outside edges of an adjoining j-channel.

Jalousie:

Made up of horizontally mounted louvered glass that abut each other tightly when closed and extended outward when cranked open.

Jambs:

The vertical parts of the frame on both sides of the window.

Kryton gas:

An odorless and colorless gas that replaces air between two or more glass panes. Krypton is denser than air and works better to deter heat transfers.

Laminated glass:

Two or more sheets with an inner layer of transparent plastic to which the glass adheres if broken. Used for overhead, safety glazing, and sound reduction.

Light:

Another term for a pane of glass used in a window.

Lock rail:

The horizontal part of a sash where the cam lock is attached.

Low-e glass:

Low-e coatings are generally neutral in appearance and designed to reduce heat loss through the glass from inside the building. The coating reflects long-wave energy and subsequently reduces the u-value of the glass. Low-e coatings may also be incorporated into solar control coatings to provide both benefits of retaining heat in the building and reflecting heat from the sun providing improved energy control.

Main frame:

Includes the head, sill and jambs of a window.

Mullion:

An intermediate-connecting member used as a means to “join” two or more window products together in a single rough opening.

Muntin bar:

A small bar that divides window or door glass.

Obscure glass:

Any type of glass with uneven surfaces which offers light diffusion and privacy.

Outer pane:

The pane of double-glazed unit which faces the exterior of a building.

Pane:

A light or sheet of glass.

Patterned glass:

Presents uneven surfaces with different impressed patterns.

Picture window:

Stationary and framed so that it is usually, but not always, wider than it is tall to provide a panoramic view.

Plate glass:

Polished plate glass is a rolled, ground and polished product with true flat parallel plane surfaces affording excellent vision. It has less surface polish than sheet glass and is available in thickness varying from 1/4″ to 1-1/4″. Now replaced by float glass.

Plumb:

Refers to a unit that is vertically level.

Retrofitting:

Adding or replacing items to existing buildings. Typical retrofit products are replacement doors and windows, insulation, storm windows, caulking, weatherstripping and vents landscaping.

Visible light transmittance:

A percentage of light that is transmitted through glass. The higher the number the more light is transmitted through the window.

Safety glass:

Glass which must have passed an impact test and either must not break or must break safely.

Sandblasting:

Creating designs on the surface of glass by using high-pressure air mixed with sand applied to the surface of glass to carve texture.

Sash:

The portion of a window which includes the glass and the framing sections which are directly attached to the glass. Not to be confused with the master frame into which the sash sections are fitted.

Sidelights:

Narrow fixed units mulled or joined to door units to give a more open appearance.

Silicone:

A polymeric organic compound offering excellent resistance to cold, heat and water.

Single glazing:

The use of single thickness of glass in a window or door.

Single-strength glass:

A term used to describe glass with a defined thickness (2.16-2.57 mm).

Slider window:

A slider window may have one or two movable panes of glass. Whatever the type, the windows slide horizontally in the frame.

Spandrel glass:

The area of glass panels that conceal structural building components such as columns, floor slabs, heating, ventilating and air conditioning (hvac) systems, electrical wiring and more.

Stiles:

The vertical parts of a sash.

Tempered glass:

Tempered glass is two or more times stronger than annealed glass. When broken, it shatters into many small fragments, thus preventing major injuries. Also known as “toughened glass.”

Triple glazing:

Three panes of glass enclosing two hermetically-sealed air spaces.

Transom window:

A window located directly above a door opening.

U-value:

Refers to how much heat passes through the glass. The lower the u-value, the better the insulating quality.

UV block:

A measure of the percentage of ultraviolet rays blocked from being transmitted through the glass. A higher uv block indicates that fewer rays are transmitted through the window.

Vinyl glazing:

Holding glass in place with extruded vinyl channels or roll-in type.

Wet glazing:

Uses a silicone-based substance to secure and seal glass to a sash.

Weep holes:

Small openings on the exterior sill designed to allow water that might otherwise accumulate in a window’s sill to escape.

Weep flaps:

Weep holes covered with vinyl to let water escape while keeping bugs out.

Wind load:

The pressure acting on an external surface of a building caused by the direct action of the wind.

Window wall:

A metal curtain wall of the commercial type, in which windows are the most prominent element. Also refers to smallest fixed lights used with wall systems.

Wire glass:

Polished or clear glass that is 1/4″ thick. Wire mesh is embedded within the glass such that the glass will not shatter when broken. The wire pattern is available in many types. It is frequently used in skylights, overhead glazing and locations where a fire-retardant glass is required.

Paul Rabinowitz Glass is a commercial glass installation, maintenance and repair business, located in Philadelphia, PA. www.rabglass.com

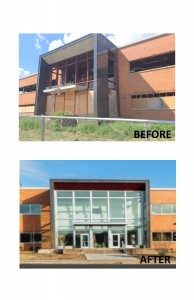

Paul Rabinowitz Glass was proud to be the glazing contractor for the historic renovation of a top charter school in Trenton, New Jersey. The charter school, which covers 80,000 sq. ft. spread over two floors, will house over 500 students.

Paul Rabinowitz Glass was proud to be the glazing contractor for the historic renovation of a top charter school in Trenton, New Jersey. The charter school, which covers 80,000 sq. ft. spread over two floors, will house over 500 students.

A smoke baffle is a substantial, noncombustible curtain that is hung tightly against a ceiling. Smoke baffles cordon off sections of a large ceiling for fire prevention purposes. A smoke baffle acts as a partition and “corrals” heat and smoke in the event of a fire within the curtained area. The depth of the heat and smoke contained within the curtained area can affect how quickly sprinklers are activated.

A smoke baffle is a substantial, noncombustible curtain that is hung tightly against a ceiling. Smoke baffles cordon off sections of a large ceiling for fire prevention purposes. A smoke baffle acts as a partition and “corrals” heat and smoke in the event of a fire within the curtained area. The depth of the heat and smoke contained within the curtained area can affect how quickly sprinklers are activated.